When developing the API forming step, few questions generate stronger opinions.

The crystallisation scientist is literally caught in the middle between the formulator, looking for consistent physical properties, and the synthetic chemist, focussed on high yield and a simpler route.

This is a question that is project specific but here are some points to consider.

At the outset, develop a separate API forming step

It’s much easier to develop a well understood process where the inputs themselves are fixed. The basic information and decisions, like solvent selection, solubility curve, metastable zone width, seeding parameters, scale sensitivity, polymorphism studies, formulation sensitivity etc. can be made without any concern of ‘Perhaps it was the impurity profile that made xyz happen!’

Decoupling the API forming step from the synthesis steps allows the synthetic chemist to focus on getting the purity and yield right without having to worry about the potential change in physical properties impacting the formulation.

If possible, back-integrate the API forming step into the last synthetic step

This where the really hard work starts. The advantages of having a combined synthetic and API forming step are obvious in terms of yield and potential reduction in complexity. However, it requires the synthesis and the formulation step, as well as the API step, to be well understood. Depending on the clinical timeframe, there may not be the time to do this at all.

Some criteria that might be used to help with the decision to back-integrate are laid out below. Answering ‘yes’ to most of these is more likely to lead to success:

- Cost of goods is high

- Clinical timeline is longer

- API loading in formulation is low

- Formulation is a simple immediate release oral solid dosage form

- The purity and concentration from the chemical step can be easily measured and controlled

- The formulation is less sensitive to changes in API physical properties

Much of this boils-down to the reproducibility of the synthetic step and the formulation sensitivity.

A real-life project example

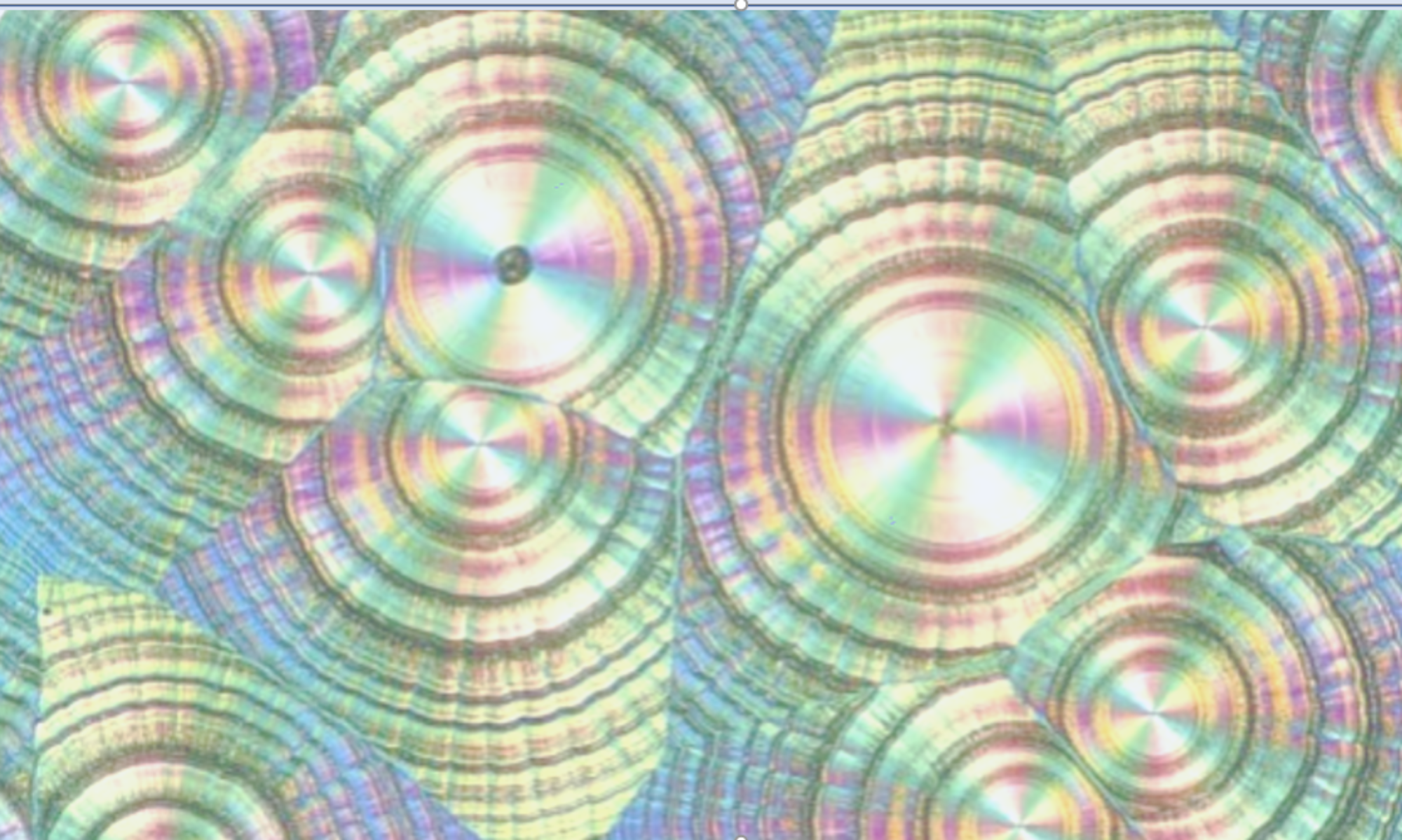

This isn’t the place for a full development history report, but this is a real example. This API had a problem with high fines content causing punch sticking on the tablet press. A separate API forming step (single solvent, seeded, cooling cryst) was developed and demonstrated at plant scale and shown to give highly consistent PSD.

In terms of the criteria set out above, the cost of goods was high, the clinical timeline was long and the formulation was simple. However, the API loading was very high (80%) and the formulation was sensitive to changes in physical properties. Crucially though, the final synthetic step could be well controlled in terms of purity and concentration. Weighing up all of these factors, the recommendation was to combine the final chemical step with the API crystallisation.

This was successful and the combined process could deliver a controlled and consistent PSD. The process was further developed in terms of QbD, and is now in commercial supply.

To summarise, always develop a separate API forming step at the beginning and analyse the risks in your project carefully before developing a combined final step. Good luck!