The properties designed into the API step during the crystallisation need to be retained during filtration, washing and drying. Common problems encountered include slow filtration, solid state form changes and reduction in powder flow due to particle attrition in agitated dryers.

Example of Skills and Experience

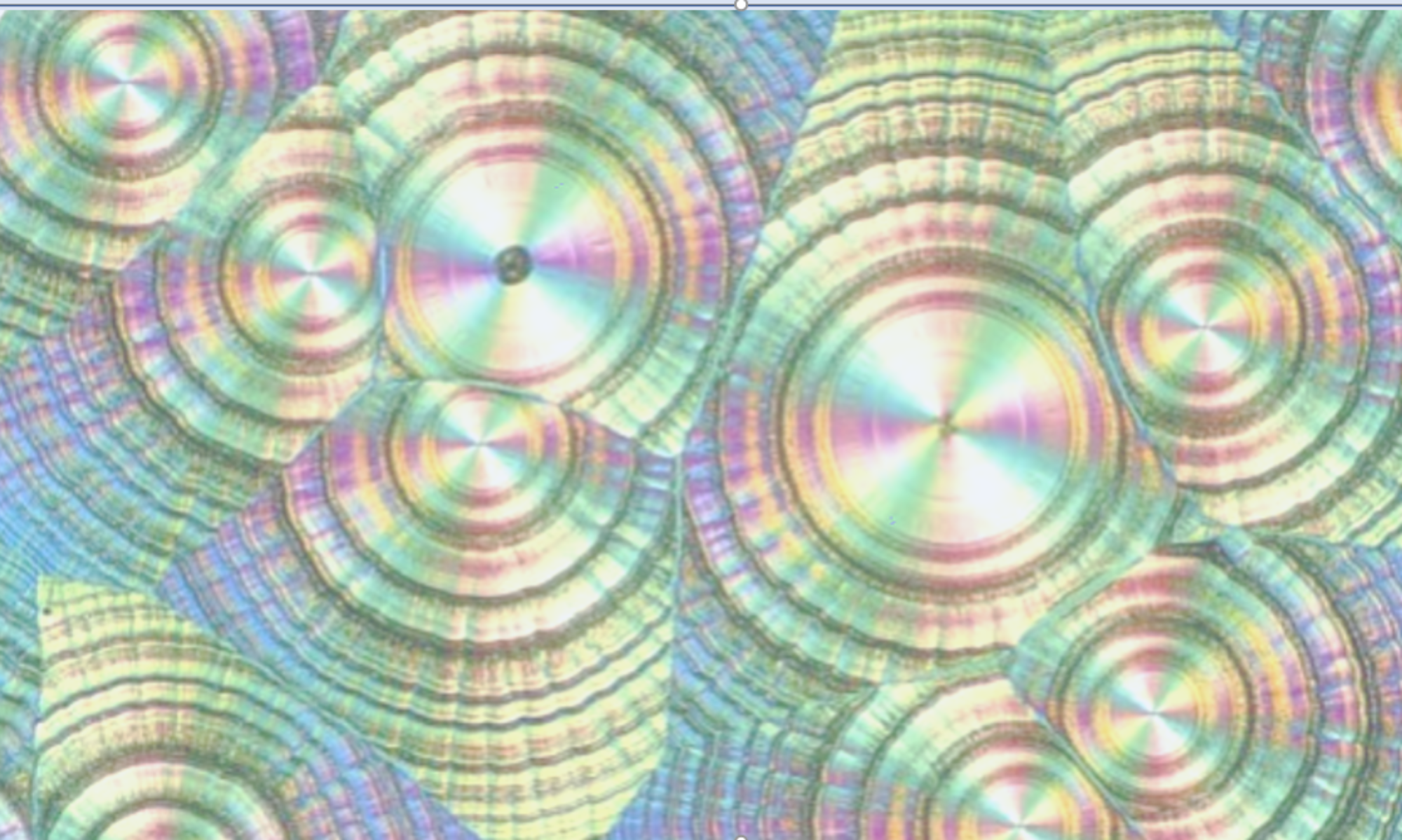

A solvate was selected as the developable form for an oncology drug. Desolvation was a risk during washing. The anhydrate was very insoluble in biorelevant media potentially leading to a loss of efficacy. The kinetics of the desolvation were measured and applied to the design of the Proven Acceptable Ranges for the filtration step.

See https://doi.org/10.1016/j.jcrysgro.2011.05.023 for an example of solvate development and QbD in filtration and washing.