The API step is the most important in the synthesis delivering purity, version stoichiometry, polymorph and hydration state as well as other physical properties such as particle size distribution (PSD) and powder flow. Complexity should be designed out to avoid issues on scale and to simplify the experimentation needed for a QbD description in the regulatory filing. A single solvent seeded cooling crystallisation is strongly recommended.

Example of Skills and Experience

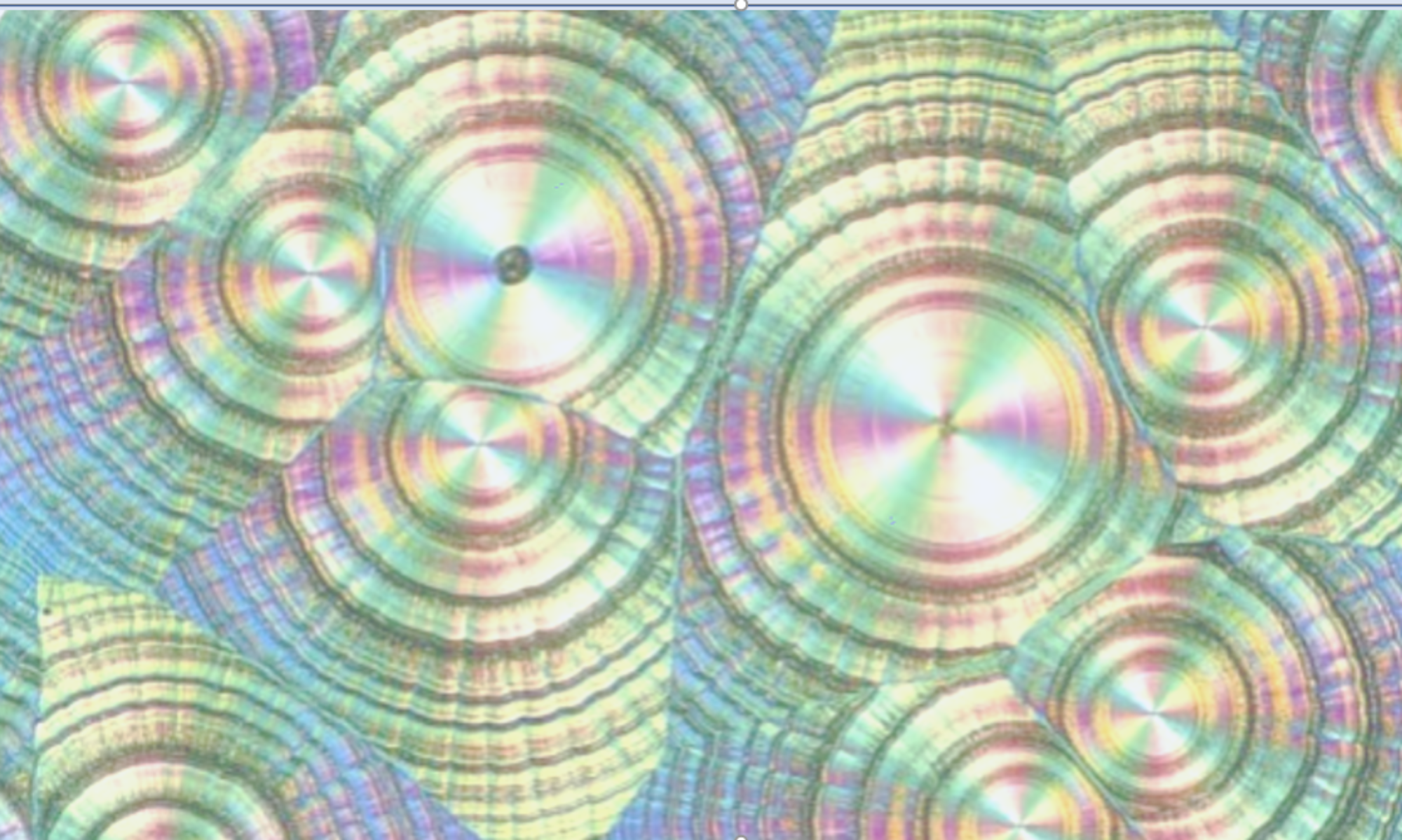

A tablet formulation for a BCS class 2 drug required very tight control of API PSD. Below the lower limit of PSD, sticking on the tablet punch occurred, and above the upper limit, tablet capping and lamination was found to be a problem due to the unusually high Youngs modulus and the 80% loading of drug. The lower and upper limits for PSD were determined in collaboration with formulation colleagues ensuring that these were as wide as possible in terms of formulation components and process operation. A single solvent cooling crystallisation was designed using micronized seed and a seed response curve to deliver API of consistent and controlled PSD. The drying step was conducted without agitation to maintain the integrity of the particles. As a result, the drug was tabletted at scale with minimal batch failure and is now in commercial production.

See https://doi.org/10.1021/op0000778 for an example of using a seed response curve.