Finding the right version of a drug is one of the most important decisions made in development. Often however, the salt screen provides far fewer hits than might be expected and sometimes none at all. As proton transfer is the fastest reaction in organic chemistry, this isn’t due to problems of reaction rate. I had a recent example of this and it made me think about some possible reasons.

1. Degradation

The API purity in the early stage of development is typically 98-99%. In my own experience, crystallisation can be inhibited at less than 95% which means that if the parent degrades even a little during the course of the salt screening experiment, then a ‘hit’ won’t be obtained.

It’s important therefore to understand solution stability and design the screen to accommodate this.

2. Is the difference in pKa between the acid and base really greater than 2 units?

It is generally accepted that a difference of at least 2pka units between the parent and the salt former is needed for complete proton transfer. However, these pKa values are generally measured or estimated in aqueous systems and not in the mixed aqueous/organic solvents used in the typical salt screen. Roger Davey et al1 performed a fantastic piece of research 13 years ago forming salts of Ephedrine (pKa 9.74). For weak acids, the actual pKa in organic solvents was shifted markedly compared to the pKa measured in water. This meant that in many cases a salt couldn’t form as protonation wasn’t complete. Consequently, those conditions returned a negative hit in the screen.

The pKa of weak acids in organic solvents can be estimated using a number of methods,2 could these be applied routinely in screen design?

3. What about pHmax?

The pHmax3, calculated from the solution speciation, the solubility product of the salt (Ksp) and the intrinsic solubility, is also an important value. For a weakly basic parent and an acid salt former, the salt is only stable in solution at a pH lower than the pHmax (the converse being true for acidic parent molecules). So for systems where the pHmax is relatively low, only strong acids will produce a hit.

Of course, Ksp won’t be known for a species that has never yet been crystallised, but the intrinsic solubility (so long as the parent has been crystallised at reasonable purity) and the speciation, will be known. So an estimate of the pHmax would focus the selection of salt formers used in the screen and increase the probability of getting hits, and hits that will survive the rigours of product development without dissociating once formulated.

To conclude, the number of hits in a salt screen could be improved by better understanding of degradation and exclusion of those conditions where this is particularly pronounced. The pKa values of the parent and the salt former in organic solvents should be accounted for and should differ by at least 2 units. Finally, the pHmax should be estimated and those experiments where dissociation is likely, should be excluded.

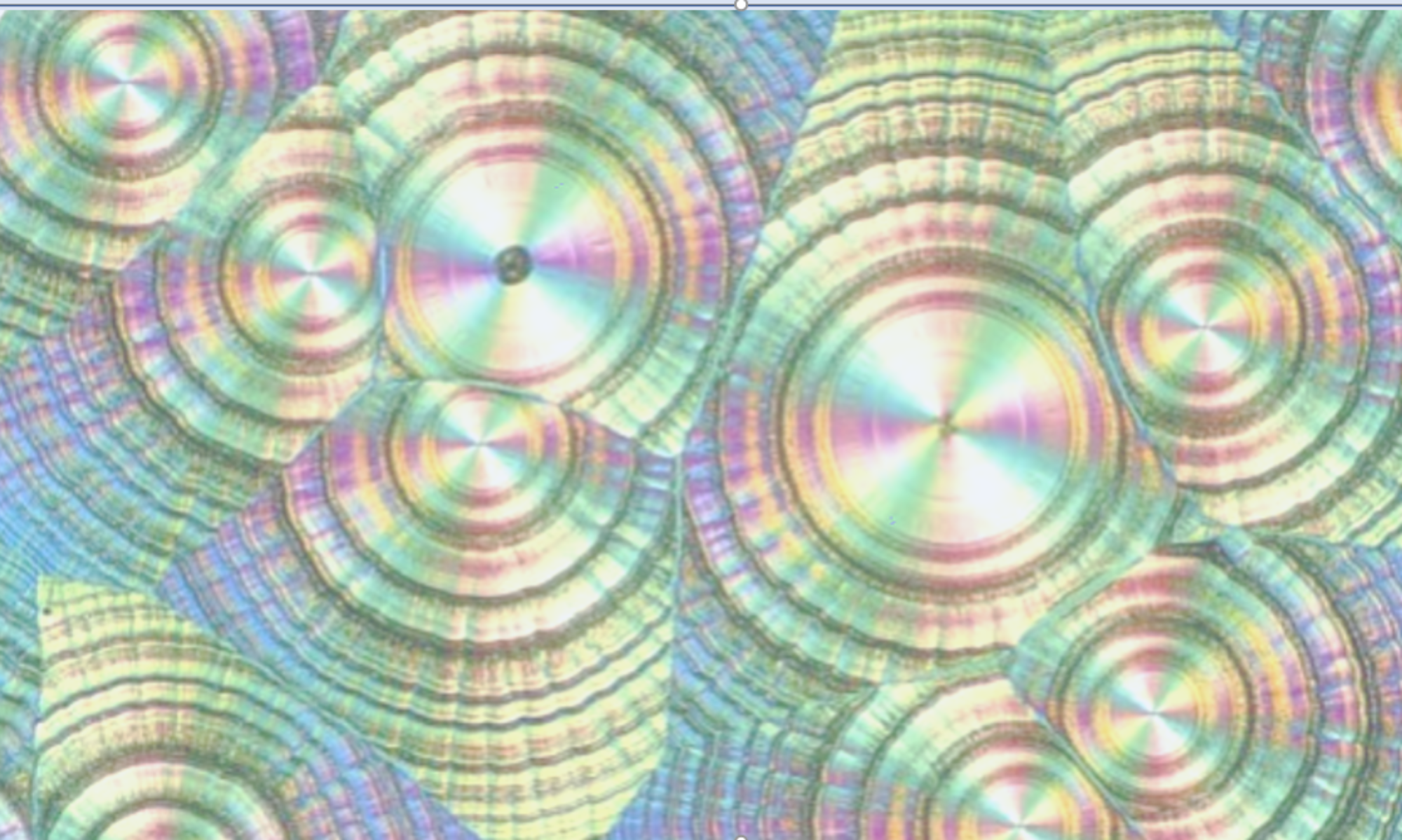

If all of this is implemented the problem becomes one of facilitating nucleation and crystal growth. Perhaps a subject for another day.

- Black, S.N., Collier, E.A., Davey, R.J. and Roberts, R.J. (2007), Structure, solubility, screening, and synthesis of molecular salts. J. Pharm. Sci., 96: 1053-1068.

- Leito, I. et al. (2018), pKa values in organic chemistry – Making maximum use of the available data. Tetrahedron Letters 59 (42): 3738-3748

- Serajuddin, A.T.M. (2007) Salt Formation to Improve Drug Solubility. Advanced Drug Delivery Reviews, 59: 603-616.

Hi Alan – thanks for the questions. On the estimation of pHmax, Serajuddin (2007) provides examples of how pHmax is…

Thanks for publishing this instructional article. This is the first time I had heard of pHmax. It will be interesting…

Thanks for publishing this instructional article. This is the first time I had heard of pHmax. It will be interesting to hear how this can be estimated.

Would also be interesting to know your thoughts on solvent quality, particularly around low levels of water in ‘winchester-grade’ solvents.

Hi Alan – thanks for the questions. On the estimation of pHmax, Serajuddin (2007) provides examples of how pHmax is shifted with unit changes in pKa, intrinsic solubility and Ksp. It’s the latter that is unknown as the species will not have crystallised yet. So the question then becomes ‘What does Ksp need to be to give acceptable pHmax?’ It might be that the Ksp estimate leads to a very high solubility and one that is unfeasible. This should lead to the exclusion of that co-former from the screen. I think this is how I see the pHmax estimate being used in screen design. Of course pH is measured in aqueous systems so this exclusion would be based on predicted dissociation risk for aqueous conditions in the screen and dissociation in the microenvironment of the formulation if that salt were selected. How pHmax plays out in non-aqueous systems where there may be limited ionization is a more complicated question. If the intrinsic solubility also isn’t known, then all bets are off. On the water content of solvents, my recommendation would be to know the quality of solvents that are being used, but given that these expts are at small scale, avoiding ingress of water is probably impossible. This is, by the way, a common problem on automated liquid handling platforms. My suggestion would be to start measuring typical water contents in screening experiments and then rationalise how this might impact the output from a screen. This would tell you if better control were needed. Hope this helps. And thanks again for the question. Robert