So you have a great drug molecule and need to turn it into a solid to progress clinical trials and product development. The molecule itself crystallises but the solubility is just too low. This is when Bioenhancement, which basically entails increasing drug solubility, can be deployed. There are a myriad of techniques out there and finding the right path is tough, hence the title of this post.

Techniques include the following:

- Salt formation – used widely and enhances aqueous solubility through ionisation.

- Particle size reduction – Normally through micronisation, increases available surface area to dissolve the drug more quickly but doesn’t effect equilibrium solubility.

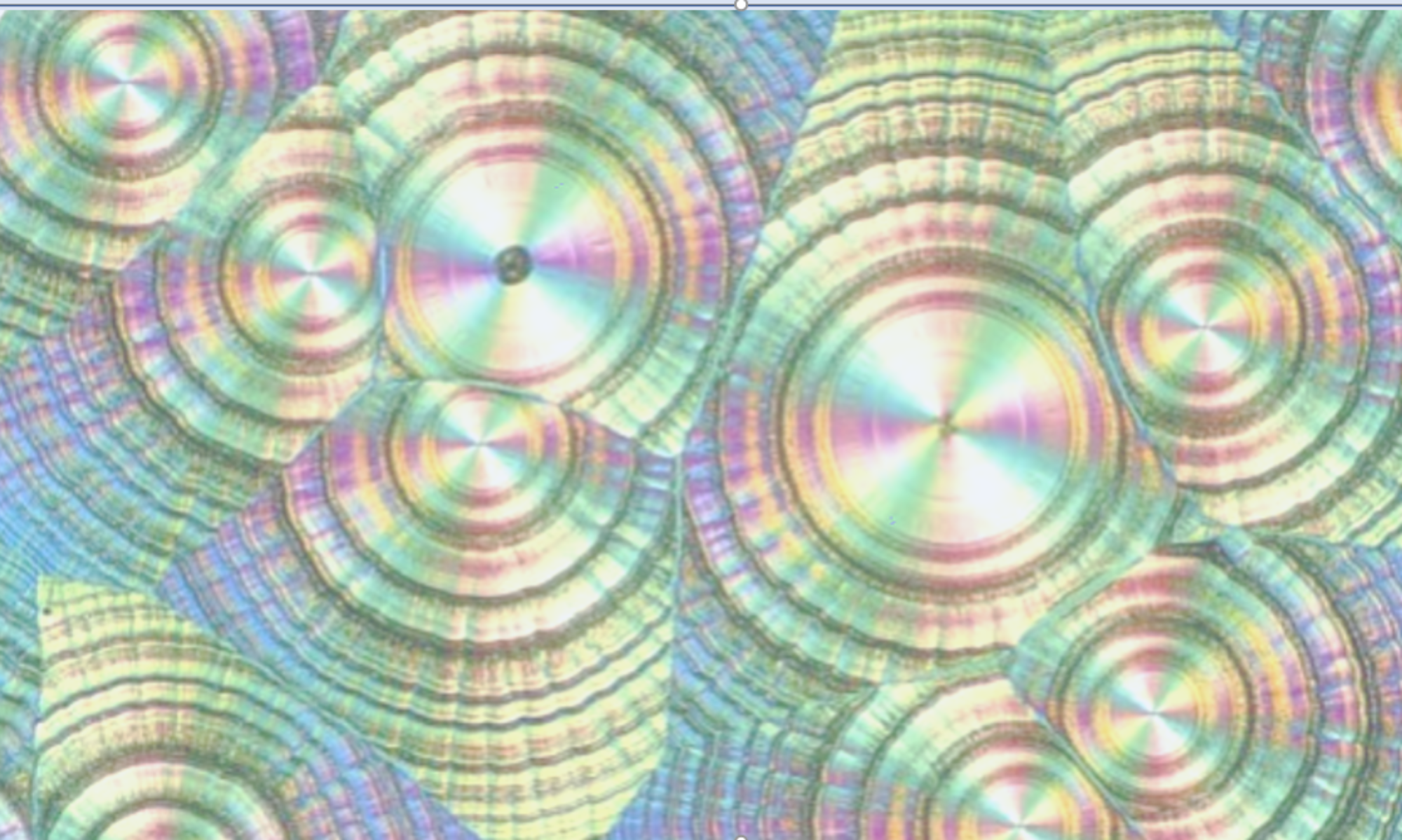

- Cocrystal formation – applied much less widely than salt formation due to issues with dissociation, precedence and increased molecular weight.

- Amorphous dispersion – normally the first stop if a crystalline soluble version can’t be identified. Amorphous solids have higher solubility relative to crystalline solids as there is no lattice energy to overcome on dissolution. But. there is a potential penalty to pay in physical and chemical stability.

- Nanomilling – reducing particles to sub-micron sizes increases the equilibrium solubility but particle growth is a risk so nanoparticles normally require some degree of stabilisation in the formulation. Complex manufacturing.

My advice is always to make sure the salt formation work is performed credibly and if that doesn’t deliver the solubility, stability and manufacturability you need, then pick your way carefully through the jungle.